" I recently finished my first wood board project. Here are some photos. It was an awesome experience, no plans, hand sketched, no real modern tools mostly by hand sanding, used the worst wood possible, Laurel is a hardwood great for guitars and fine furniture, but looks great and is now hanging on the wall at the local brewery in San Juan del Sur, Nicaragua (SJDS Ceveceria). I'm already starting the next one! "

Wednesday, June 24, 2015

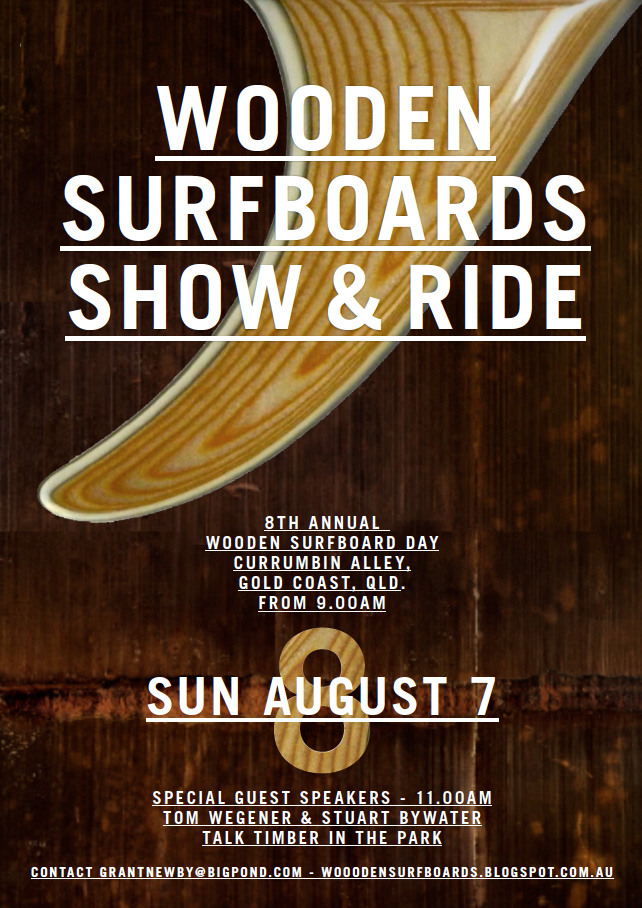

Wednesday, June 17, 2015

Wood coming to life

Don't you just love it when after all the hard work and the dust has settled, it just comes alive with colour and it makes it all worth while.

Gareth Smith surfboards and art

Gareth Smith has been crafting and

designing wooden surfboards for the last 10 years. An avid surfer and

artist his boards are made with the surfer in mind. He takes great pride

in researching, designing and replicating the boards of yesteryear.

These boards have been carefully crafted, sealed both inside and out,

and built to surf and to last.

Each board is suitable to certain waves and conditions. The weight of the wooden board provides a glide and momentum different from todays boards and is a must have for any avid surfer's collection.

Art is something that has always had pride of place on Gareth's boards and now uses his handcrafted wooden boards to display and compliment his functional artwork.

For more information or to order a beautiful one off board : www.gwswoodensurfboards.com

Each board is suitable to certain waves and conditions. The weight of the wooden board provides a glide and momentum different from todays boards and is a must have for any avid surfer's collection.

Art is something that has always had pride of place on Gareth's boards and now uses his handcrafted wooden boards to display and compliment his functional artwork.

For more information or to order a beautiful one off board : www.gwswoodensurfboards.com

Sunday, June 14, 2015

Lesley's new board

Lesley Adamski is the only lady I know of who has built more than one chambered surfboard. This is the second one I know of but she has built other wooden boards.

The board is made from a Coral Tree which anywhere on the east coast is known as a weed! This one was from a roadside bush poisoning. It's very light when dry.It's a chambered construction which took an awful lot of thinking and work to actually get it together. Those cross grain marks are from having to straighten that piece because it had a compound curve. Because it was so hard to get together I had to guess the internal cutouts before gluing up so the 6kg weight is a nice surprise. The shaping was the easy part. The timber is very fibrous (ropey actually) when still green but if it were possible to mill some slabs it would be easier as a hollow construction. I love the different grain especially the spalting. The timber had a strange hollow core, notice what look like dowels in some areas.They're made from coral tree too. The dark timber is western red from a salvaged handrail and the fins are Aust cedar.

So very happy with the board made from a weed. I've only epoxy resined it with entropy supersap.

No glass to keep weight down to just over 6kg. And it surfs very well .

The board is made from a Coral Tree which anywhere on the east coast is known as a weed! This one was from a roadside bush poisoning. It's very light when dry.It's a chambered construction which took an awful lot of thinking and work to actually get it together. Those cross grain marks are from having to straighten that piece because it had a compound curve. Because it was so hard to get together I had to guess the internal cutouts before gluing up so the 6kg weight is a nice surprise. The shaping was the easy part. The timber is very fibrous (ropey actually) when still green but if it were possible to mill some slabs it would be easier as a hollow construction. I love the different grain especially the spalting. The timber had a strange hollow core, notice what look like dowels in some areas.They're made from coral tree too. The dark timber is western red from a salvaged handrail and the fins are Aust cedar.

So very happy with the board made from a weed. I've only epoxy resined it with entropy supersap.

No glass to keep weight down to just over 6kg. And it surfs very well .

We hope to Lesley and her boards at the wooden board day again this year.

Saturday, June 13, 2015

Sergi in Spain - new board build

Llamanto F2 – 5ft 3" x 20 5/8" x 2 5/8"

"It's a reinterpretation of my hollow Llamanto. Considering it's 1'5kg lighter I redisigned it thinking of a more aggressive surfing, not so "speed oriented" and looking for tighter turns.

I ordered recycled EPS blanks in different sizes and three different rockers. All my designs fit into one of those three. That way I can pick the blank I need, cut the outline and glue the rail bands. Then I only have to fine tune the rocker. "

"It's a reinterpretation of my hollow Llamanto. Considering it's 1'5kg lighter I redisigned it thinking of a more aggressive surfing, not so "speed oriented" and looking for tighter turns.

I ordered recycled EPS blanks in different sizes and three different rockers. All my designs fit into one of those three. That way I can pick the blank I need, cut the outline and glue the rail bands. Then I only have to fine tune the rocker. "

"And then comes the weirdest shaping process ever experienced. You're shaping something that resembles a surfboard, without rails and about 7mm thinner than it will be with the 3/4mm skins. To make it easier I print a full-scale template with a few slices of the board and some mesurements. The first rail band will determine the definitive rail height, and from that point it's "only" a matter of shaping the dome and whatever you want in the bottom."

"This time I embeded some paulownia blocks into the foam for installing FCS fins. The board had had a couple nice concaves, so I had to carefully shape those little blocks, trying not to rip the EPS. Anyway the vacuum squeezed the EPS well enough to form some weird bumps where the blocks were installed. Next time I'll try cork"

Sergi's new rail clamping process.

"The rails are made of 5mm strips, 20mm thick in the center but they go thinner towards tail and nose. And the finish is the same I do with my other boards, just a couple hands of varnish for wood floors. And yes, I had some fun with water colours! "

Great looking board from Sergi. I am sure this will not be ghis last using this building method now that he has his head around it. Just wanting for the ride report.

Thursday, June 11, 2015

Check out the Grain website

The boys at Grain have revamped thier site and have a great looking range of boards on the go.You can check them out in 3D and it is all very well explained. Nice.

Tuesday, June 9, 2015

There are many ways to skin a cat and even more ways to skin your board.

Check it out , the latest video from John Purnell's Deep Creek TV. Recycling a snapped PU board and giving it a new life wrapped in Paulownia.

Wednesday, June 3, 2015

Mathew Ayre and his Polymath Surfcraft

His story, in his words ...

"Hit with the unmistakable smell of styrene

and through the haze of a freshly sanded longboard I met with Rob

Lion* to discuss my first custom board. Prior to this meeting I was

admittedly, totally ignorant to the world of surfcraft and in visiting

my board during the varying stages of it’s creation I was witness to

Rob’s willingness to experiment with concepts, shapes and materials. The

effect was instant and is why I almost immediately stripped the glass

off an old board, eager to break the convention to which I was

unconsciously adhering.

With more

enthusiasm than method I hacked away at the unceremoniously stripped

back surfboard. What ensued can only be described as a waste of what was

a perfectly usable board. I decided making boards was a stupid idea.

Despite

feeling disheartened at this failure I couldn’t quash my curiousity and

I began to read around surfcraft and it’s construction. With my freshly

gleaned knowledge I ordered my first real blank. This attempt

was relatively successful and I started to build experiment after

experiment, manifesting my on going research in tactile form.

As

I continued to experiment, other like-minded surfers began asking for

boards and soon I was receiving regular orders, refining my skills and

processes with every board. Five years on I began to question the

methods I was using, that smell of styrene and haze of sanding dust that

had initially sparked excitement and intrigue were now an inconvenience

to my adopted creative outlet.

Unhappy

with the dust, noise and chemicals I was exposing myself to I stopped

taking orders and began researching cleaner build methods. I had a fair

idea of where I wanted to take my work and I began a new period of

experimenting, focussed on a variation of the compsand method using

external timber veneers.

I found this

process to be much cleaner for myself, creating exponentially less dust,

noise and smell with no compromise on what I can build. The resulting

boards have a greater strength to weight ratio than those I used to

build using the accepted standard of polyurethane foam and polystyrene

resin.

Finally, limiting orders to 24 a

year allows me continue doing what has got me this far, and enjoy the

creative process. 24 is not a goal, it is a cut off point, a point at

which I believe if exceeded the pressures of meeting demand would impact

on the enjoyment I get and the quality of the boards I produce.

It is a privilege to explore the craft behind riding waves."

Subscribe to:

Posts (Atom)